We offer our customers a modern SCADA system used for monitoring and visualization of industrial facilities ...

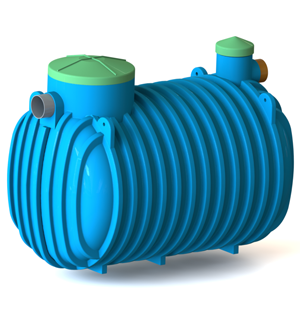

Drainage waste water treatment plant

On-site waste water treatment plants with a leaching system are waste water treatment plants for household use which can replace a septic tank. Waste water treatment in an on-site treatment plant comprises two consecutive processes.

Preliminary treatment which takes place in the tanks through the decantation process (separation) and sediment fermentation with the use of anaerobic bacteria which results in partial liquefaction of waste water.

The other phase is drainage.

The parameters of the water on completion of both of the processes described above conform with Polish and EU regulations.

Advantages

- Properly ribbed tank with vertical ribs on the bottom (a unique design solution) provides high mechanical resistance.

- Design of the (settlement) tank and its parameters conform with the harmonized PN EN 12566-1 norm.

- The tanks are produced using the newest rotational molding machine which ensures full control over the heating process, proper temperature and proper cooling. Machines of this kind guarantee high material resistance and repeatability of the production process.

- The settlement tank has been equipped in two chimneys: one for emptying the tanks and the other for assembling a filter.

Ecology

Septic tanks are 100% recyclable, raw materials can be reused.

Intended use

Summer houses, on- or multifamily houses, holiday centers, small companies, campings, tent sites, others.

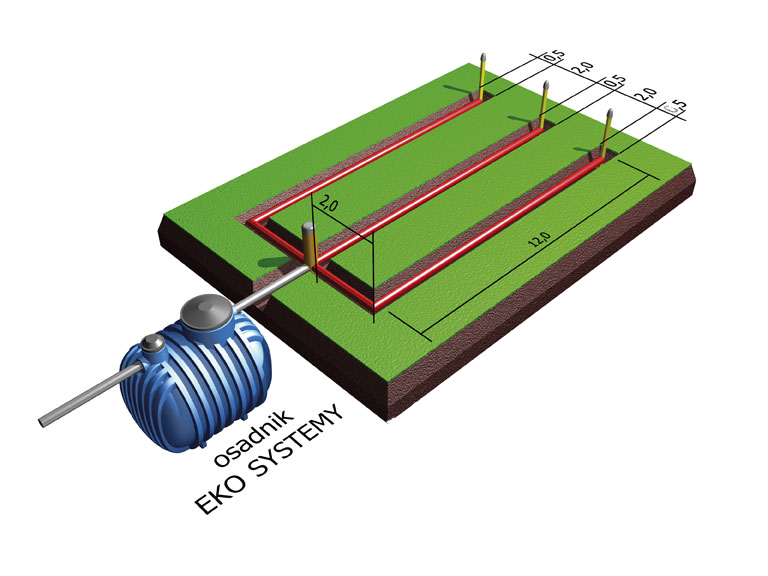

Optimally, the drainage pipe should run 60-80 cm under the ground, and should be 1-1.5% inclined and laid on a minimum layer of 20 cm of breakstone.

Above the pipe, there should be a 5 cm layer of breakstone and then a layer of geotextile.

The length of the draining pipes in the case of 2000 l tanks is 12 m on average and 16 m for a 3000 m. Maximum length is 20 m.

Example layout of the waster treatment plant elements

Presented in the advertising information and drawings are for illustration only and does not constitute an offer within the meaning of Article. 66 pairs. 1 Civil Code. In order to familiarize with the offer, please contact the sales department's EKO-SYSTEMY

![]()

- Rysunek - Zbiornik 2000L (.pdf / 552Kb)

............................................................................................................................................................................... - Rysunek - Zbiornik 3000L (.pdf / 742Kb)

............................................................................................................................................................................... - Aprobata Techniczna - IBDiM (.pdf/ 7,4Mb)

............................................................................................................................................................................... - Deklaracja zgodności - oczyszczalnia (.pdf / 597Kb)

............................................................................................................................................................................... - Deklaracja zgodności - osadnik (.pdf/ 588Kb)

............................................................................................................................................................................... - ITB - certyfikat CE (zbiornik oczyszczalni drenazowej)(.pdf / 426Kb)

............................................................................................................................................................................... - Warunki gwarancji dla oczyszczalni drenażowej (.pdf/ 999Kb)

............................................................................................................................................................................... - Wytyczne montażu i eksploatacji - oczyszczalni drenażowej (.pdf/ 505Kb)

............................................................................................................................................................................... - Wytyczne montażu zbiornika poziomego (.pdf/ 434Kb)